| Dave Ramsey et al with early HP 41C conversions to CL Message #1 Posted by geoff quickfall on 30 Dec 2011, 3:16 p.m. I thought I would start a separate thread for this as a few people have converted the old hex nut version 41C's to the CL. The hex nuts were not meant to be removed and replaced more then a few times at best. Maybe it just my clumsy fingers but read on! ______________________________________________________________ The hex nuts indicate an early 41C. Trouble sometimes is the posts are not threaded initially and reinstalling them can result in a cross threading leading to a stripped and thinner post. You are correct (from Daves posting below) as the back shell is different from later versions due to the hex nut installation. HP actually, on repairs, removed the hex nuts and replaced them with plastic spacers. These were slightly thicker then the height of the posts protruding from the logic pca. This resulted in the rear shell pressing the board onto the strips as opposed to the hex nuts doing the pressing. A simple replacement for the hex nuts would involve similar spacers or silicon tubing cut to a slightly higher height then the protruding portion of the screw posts. This would have the same affect of the rear shell compressing the pca into the zebra strips. Silicon tubing replacements for stripped hex nuts:

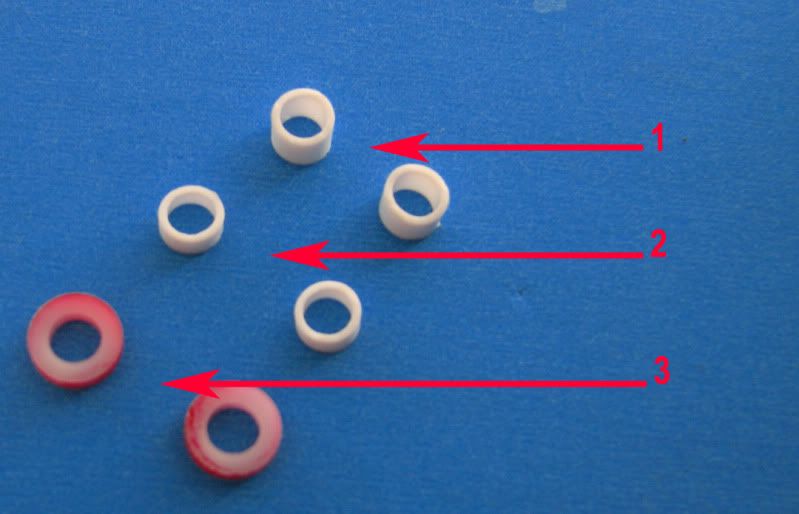

Spacers precut; #1, #2

One can also purchase styrene tubing for the top posts but this requires shaving the very tips of the battery/module block. You probably remember this from the HCC2011 presentation and the youtube copy. Shaving a tiny portion of the indicated vertical plastic from both sides of the battery/module block:

Module in place showing the new reinforcements and indicating the area of the battery/module block that needs shaving (immediately adjacent to the reinforcements on the screw posts (white):

The logic PCA plus spacers and upper post reinforcements in place:

The tubing is 7/32” or 5.5mm and also comes in brass (overkill?). As Monte states, the posts and contacts must be good, or, as I found out during a flash write, BOOOM, no more CL. Fortunately Monte re-flashed the machine successfully. But as a simple google of "flash drives power interupts during write" this can be fatal to the drive. So insure good connections. Non stripped posts, internally as well as the external hex nuts. Good elastomer (as Angel states below, how does one tell?) or wire wrapped zebras, clean pca and battery/module block contacts. Cheers, Geoff

Edited: 30 Dec 2011, 3:40 p.m. after one or more responses were posted |