Re: HP 97 card reader clutch shaft repair

Message #3 Posted by Ed Sowell on 15 May 2010, 7:07 p.m.,

in response to message #2 by geoff quickfall

Quote:

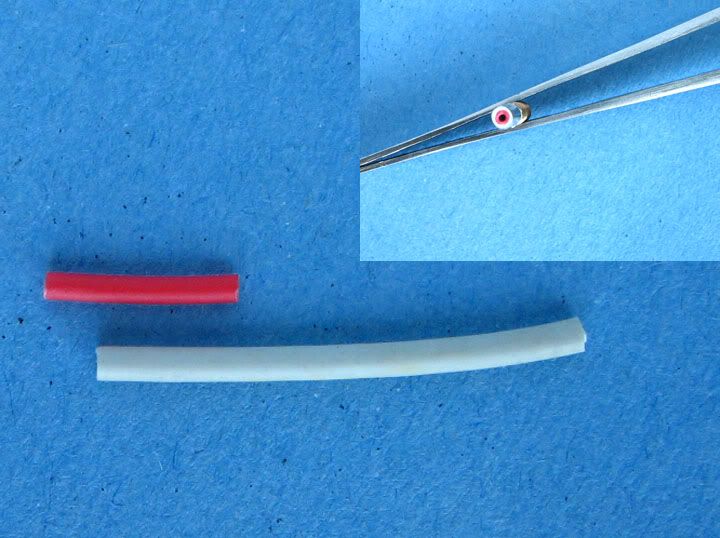

I have never done the repair this way as I favour the insulation method.

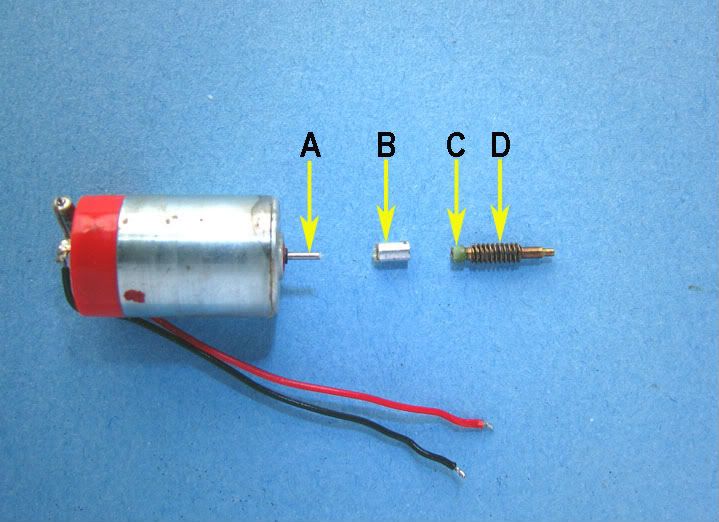

I pursued the insulation method for a while but abandoned it because I couldn't find a suitable piece of insulation. It seems to me that a size that gives a good fit on the motor will be too tight on the worm shaft. Also, I wanted to fit the aluminum sleeve over it, but that would leave a very thin wall over the worm shaft.

Quote:

Remember that there is a ball bearing at the tip end of the worm gear. This will cause end shake if it is missing, it is tiny!

I've noticed that. On mine it seems to be peened in on the opposite side of the frame so did not fall out.

Quote:

How do you centre the shaft with the silicon method. The wobble of an off centred system would cause a lot of vibration. After all this is a dampening couple and not a clutch.

When I did it the first time I followed advice given in previous posts by others: let it harded a few minutes then push it around a bit till it looks OK. All this is done with the motor vertical with the shaft up.

This time I am going to try to put the motor/worm shaft assembly into the frame after the silicone has hardened a bit. I think this will allow better centering, at least for the worm shaft, since it will be in its pivot hole at one end and on the motor shaft at the other. The only thing that can be off center is the sleeve, and that can be minimized by pushing it around a bit with a small screwdriver to get the gap between the sleeve in the frame hole even all around. Also, I will be able to get a better axial fit.

At this point I am very encouraged by the silicone method. It is really not very difficult. My desktop bench vice makes it a lot easier. For example, the frame can be held in any position you want while fiddling with the motor and worm gear. Also, I squeeze the silicone directly into the sleeve using the smallest possible cut on the silicone nozzle. Not messy at all that way.

Quote:

I take it you have not swapped parts from another calculator system as for example, the HP 42 card reader assembly (looks identical) is not the same length as the HP 65 system:

Nope. So far, I've found everything I've lost. Even that tiny nylon washer! (BTW, what's it for?)

Quote:

As far as end shake goes, all my systems have been very close to a tight fit and the bearing acts as it should. That is there has been no endshake. Having said that, other then vibration I don't see a problem with some other than noise.

So maybe the bearings in my motor are worn out?

Thanks for your help. I'm in no hurry with this project so it may be a while, but I'll report back with lots of photos when I'm finished.

Ed

Edited: 15 May 2010, 7:13 p.m.

|