Re: 9810 Magnetic card options

Message #9 Posted by Tony Duell (UK) on 21 Aug 2003, 5:16 p.m.,

in response to message #7 by Andy

When you say 'exact' dimensions, how 'exact'? Do you want me to dig out the travelling microscope (yes, I do have one), or are the following dimensions, measured with a ruler, good enough?

The short card, part number 9162-0012 measured 6" long by 2" wide. The long card, part number 9162-0045 is 10.5" long by 2" wide.

There is, AFAIK, no pre-fomatting on these cards (or on the 9100 cards for that matter). The 9810 records 4 tracks in each direction (it's a 4-coil head). 3 data tracks and a clock track. Porgram keycodes on the 9810 are 6 bits long, and are recroded as 2 sets of 3 bits on the card. I am not sure how 16 bit data words are stored, probably as 6 3 bit words.

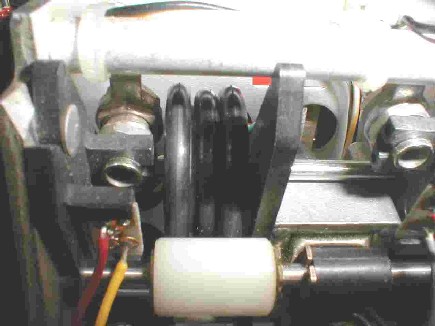

I must get round to reparing my 9810 card reader (it's got the 'stock fault' of the decayed roller, and is otherwise OK I think). I had also better figure out how the 9810 works before the HPCC conference in a couple of week's time (If there are any UK people here who would like to come to that (13th Sept in London), then e-mail me and I'll provide details).

|